Manufacturing

& line feed.

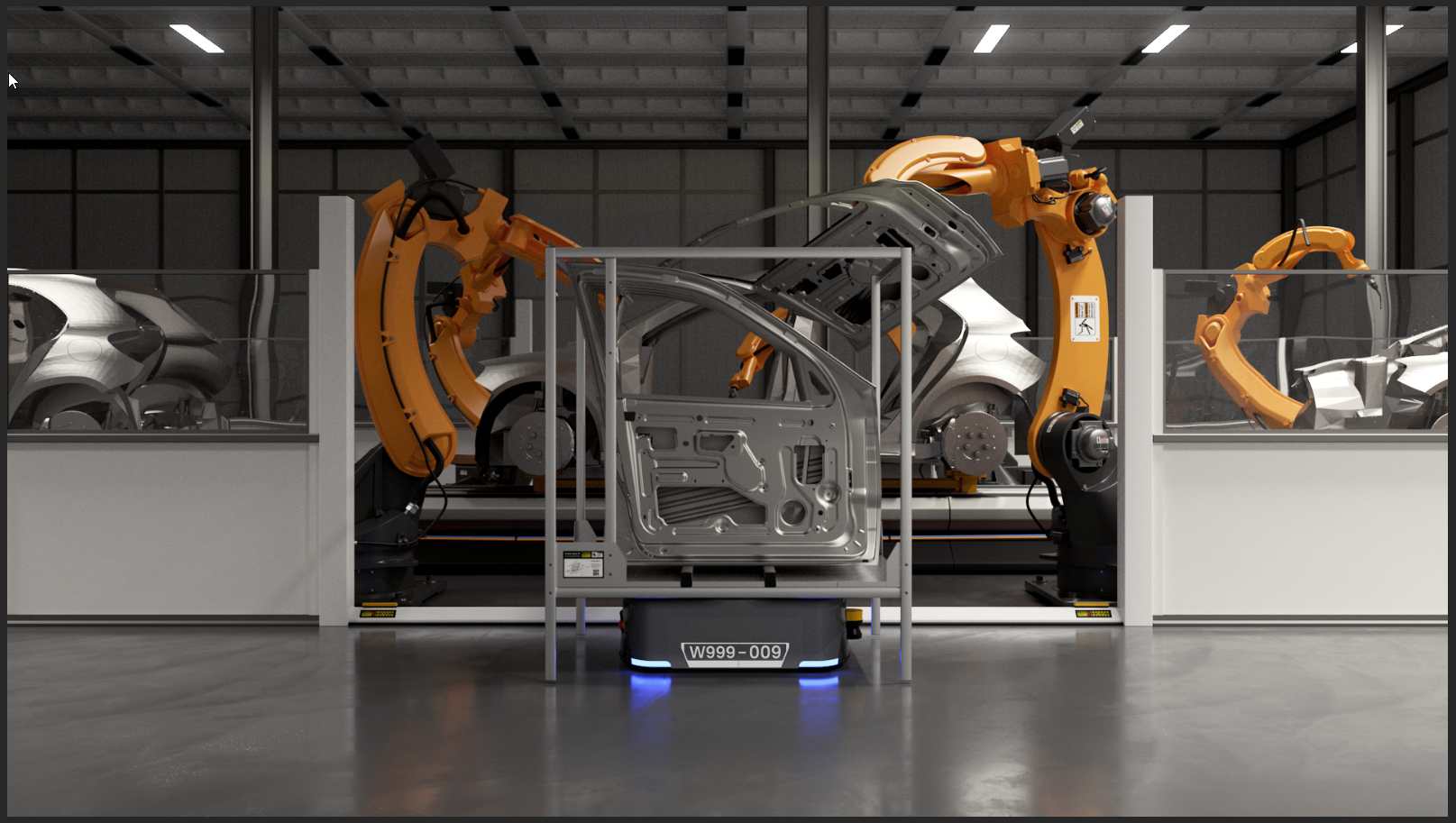

Flexible manufacturing.

Different manufacturing operations face varying challenges according to their function, whether mass manufacturing or customised assemblies. Manufacturing and assembling low batches negates any economies of scale. Creating assemblies from diverse manufactured components, each with different tack times, creates consolidation and timing challenges.

By simulating the workflow with a digital twin of the manufacturing environment, optimum performance can be established. Consolidating components through effective buffering facilitates different production times and batch sizes. Real time data of exact locations of components in the production flow enables speedy identification of all items in the production cycle.

By creating modular, scaleable & flexible lean workflows, the manufacturer can gain economies of manufacture, while reducing the number of times a component is manually handled.